A New Eco System Emerges

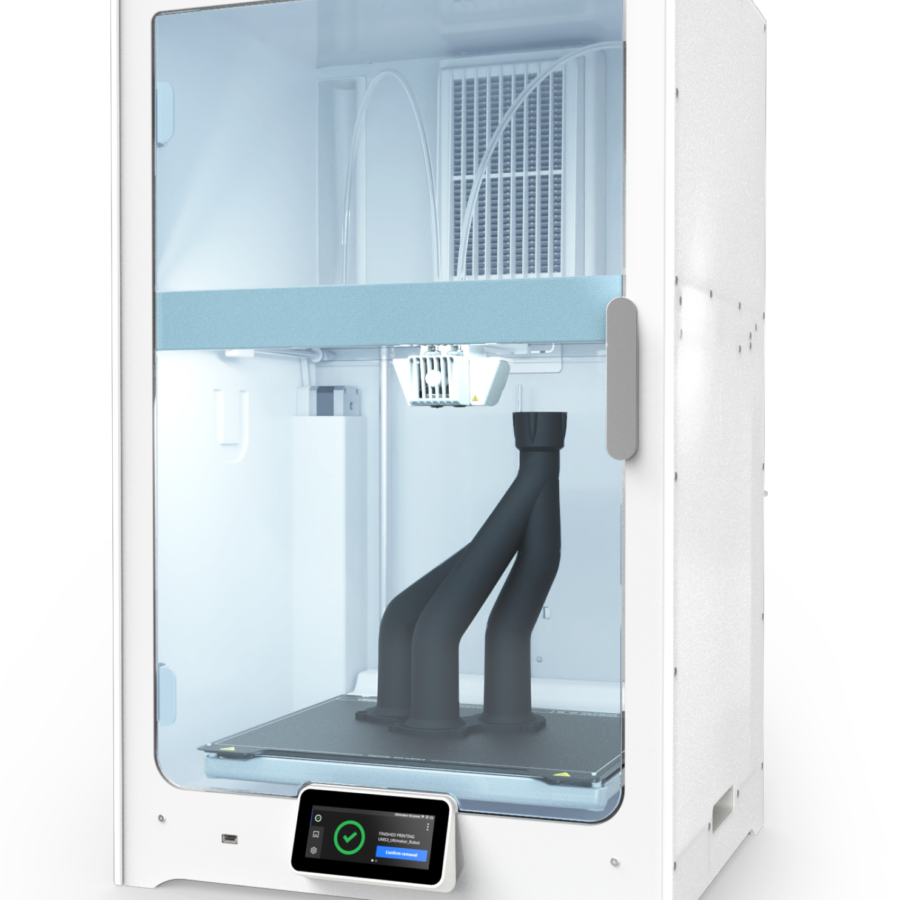

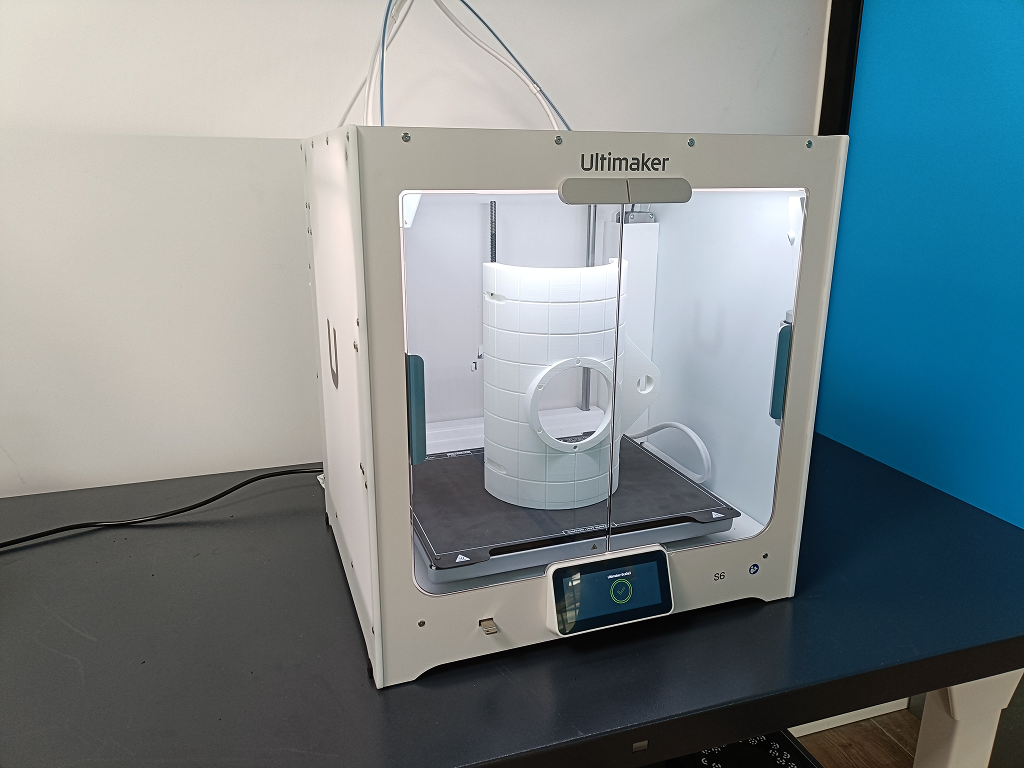

Industrial 3-D printing is going mainstream in a big way. Executives and many engineers have realized that technology has moved well beyond prototyping, rapid tooling, trinkets, and toys. “Additive manufacturing” has created durable and safe products that have revolutionized the corporate culture.

Some of the numerous companies using 3-D printing to ramp up production are GE (jet engines, medical devices, and home appliance parts), Lockheed Martin and Boeing (aerospace and defense), Aurora Flight Sciences (unmanned aerial vehicles), Invisalign (dental devices), Google (consumer electronics), and LUXeXcel (lenses for light-emitting diodes, or LEDs). With all the new developments, 3-D printing has emerged from its niche status and become a viable and reliable alternative to conventional manufacturing processes and applications.

Companies are loving the options because the range of printable materials has expanded so much and continues to expand today. The media has grown from plastics to photosensitive resins such as ceramics, cement, glass, numerous metals and metal alloys, and thermoplastic composites infused with carbon nano tubes and fibers. Superior economics will eventually convince those resisting. Although the initial cost may be higher, the greater flexibility afforded by additive manufacturing means that total costs are substantially lower.

Companies have so much more to offer because fabricating an object layer by layer, according to a digital “blueprint” downloaded to a printer, allows for customization and designs of greater intricacy without limit.

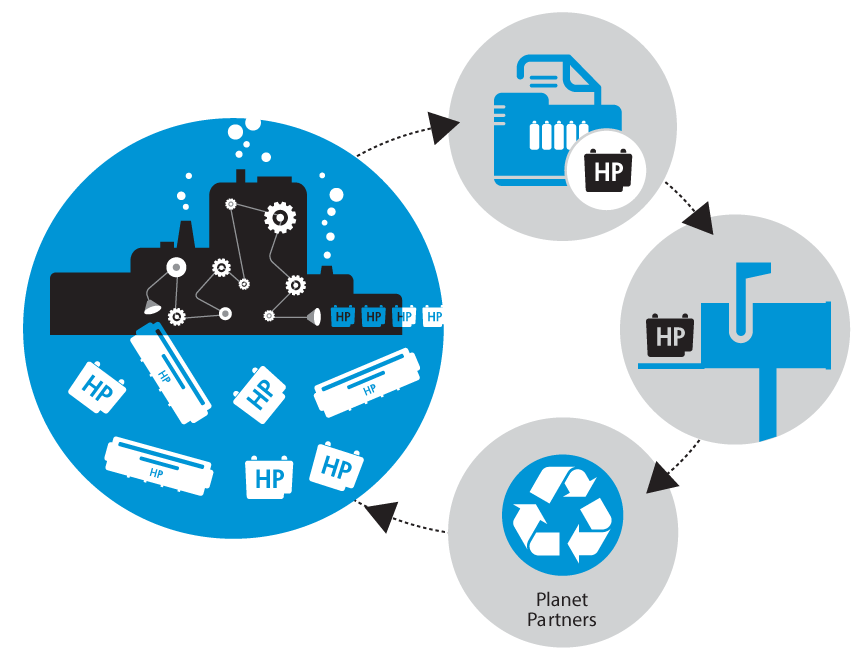

Companies can consider the strategic implications as a new ecosystem begins to form around the new realities of 3-D printing. The opportunities are endless, from cost savings to original designs. The time for strategic thinking is now!