News Letter

A printer’s ink cartridge takes 450 to 1000 years to completely decompose in a wasteland. With the printing demand increasing yearly, we can expect mountains of ink cartridges to rot away doing harm to the environment. It is up to us to remedy the waste, and that is exactly what sustainability in HP is about –self-accountability and planet preservation.

An ink cartridge is manufactured with different parts, such as an ink tank and a silicon circuit. The mechanism ensures equal ink distribution. Unfortunately, the printer’s cartridge does not represent its manufacturing waste. A manufacturer consumes more than 2 pints of oil in cartridge manufacturing. In addition, the toner requires more than 5 points of oil.

With extensive soul searching it’s easy to see you are hurting the plant each time you press Print on a document if you aren’t using a sustainable product.

We have the answer you seek! HP manufactures environmentally friendly cartridges that do not compromise on the printing quality. The strategy is to reduce landfill waste while preserving resources for future use. In addition, the sustainable option also saves money because the manufacturer does not need to produce cartridges from square one if they can be reused.

When an ink cartridge is re-used, it employs an Original Equipment Manufacturer. The quality signals that the cartridge is recycled but has been refilled with the original ink. However, eco-friendly cartridges have additional benefits

HP cartridges preserve the environment. Using Sustainable HP cartridges means the customers don’t throw away the ink component when it’s empty, and the toner stays out of the garbage too. This saves space in the landfill and prevents future pollution.

With successful implementation, emptying landfills can take the shape of nature preserves, recreational spots for families, schools, and so much more.

Manufacturing ink cartridges requires aluminum, steel, plastic, and rubber. Re-using ink cartridges saves these resources, and our environment.

HP reused cartridges means saving money too. There are no purchase or manufacturing costs if you are reusing the cartridges, the only expenses are refilling ink and repackaging. When purchasing environmentally friendly cartridges, the customer saves money while saving the planet so it’s a win-win.

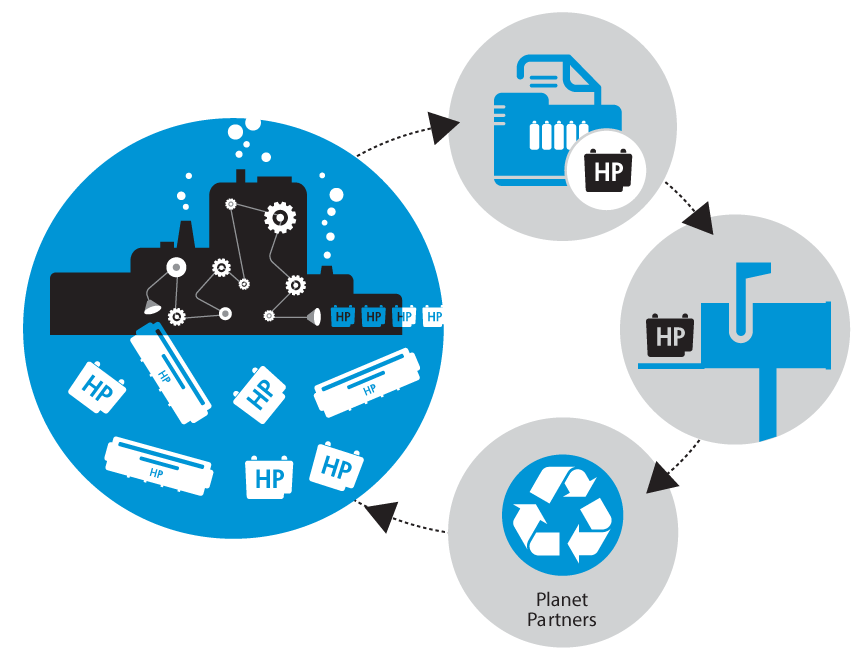

Step 1: Customers send empty cartridges to HP. The step is completed using the HP Planet Partners initiative.

Step 2: HP will sort, shred, and dismantle the cartridges. Quality assurance protocols are practiced extensively.

Step 3: The recycled plastic is combined with leftover materials to complete the materials needed for manufacturing.

Step 4: HP manufactures new cartridges using the sorted material.

Recycled HP Ink Cartridges use 36% less water and reduce carbon footprint by 46%. Moreover, recycled cartridges use 62% less fossil fuel too.

A re-manufactured HP toner consumes 33% less water and 32% less fossil fuel. In addition, the carbon footprint also reduces by 31%.

HP cartridges ensure that the air quality is not compromised, andthey meet all compliance requirements of the printing system.

HP Planet Partners Program supports and promotes recycling material to reduce waste. Moreover, HP+ Forest First Printing will restore and protect forests with NGOs for every page printed. HP guides and empowers businesses to incorporate climate preservation into their operations.

HP sustainability practices can influence industrial practices, and have a huge impact on healing our environment. Shop with the company that has sustainability in mind to become part of the bigger picture.