News Letter

$12,734.74 Original price was: $12,734.74.$11,500.00Current price is: $11,500.00.

Introducing the UltiMaker S7. We took everything our customers love about the award-winning S5… And made it even better.

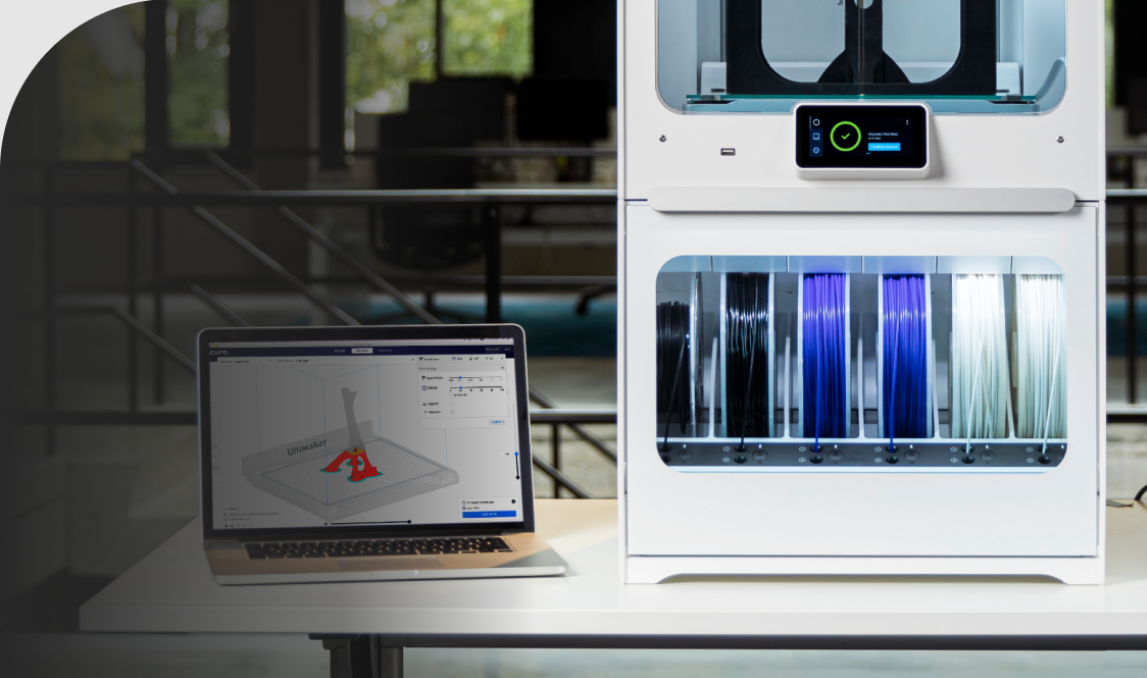

The UltiMaker S7 Pro Bundle adds the Material Station to our newest S series 3D printer, transforming it into a manufacturing powerhouse. This one-of-a-kind upgrade further simplifies the 3D printing workflow with automatic switching of up to 6 spools. And constant humidity control ensures material is delivered in perfect condition for high-quality 3D prints.

All the uptime in the world. |

Automatic material handlingDesigned to be left unattended, the Material Station allows the UltiMaker S7 to 3D print longer – day or night. Loading material into the Material Station takes seconds – not minutes. Simply open the door and drop the spool into a bay. During a print, any spool not in use can be switched out. |

Front-loading bays for 6 spools (including composites)

3D print more materials. More easily. |

Hassle-free storageEvery spool is kept below 25% relative humidity, making it easy to realize more 3D printing applications with almost any combination of polymers and abrasive composites. Each of the Material Station’s material bays have NFC readers and reinforced prefeeders for integration with UltiMaker Cura and Digital Factory. |

Materials automatically kept at 25% relative humidity

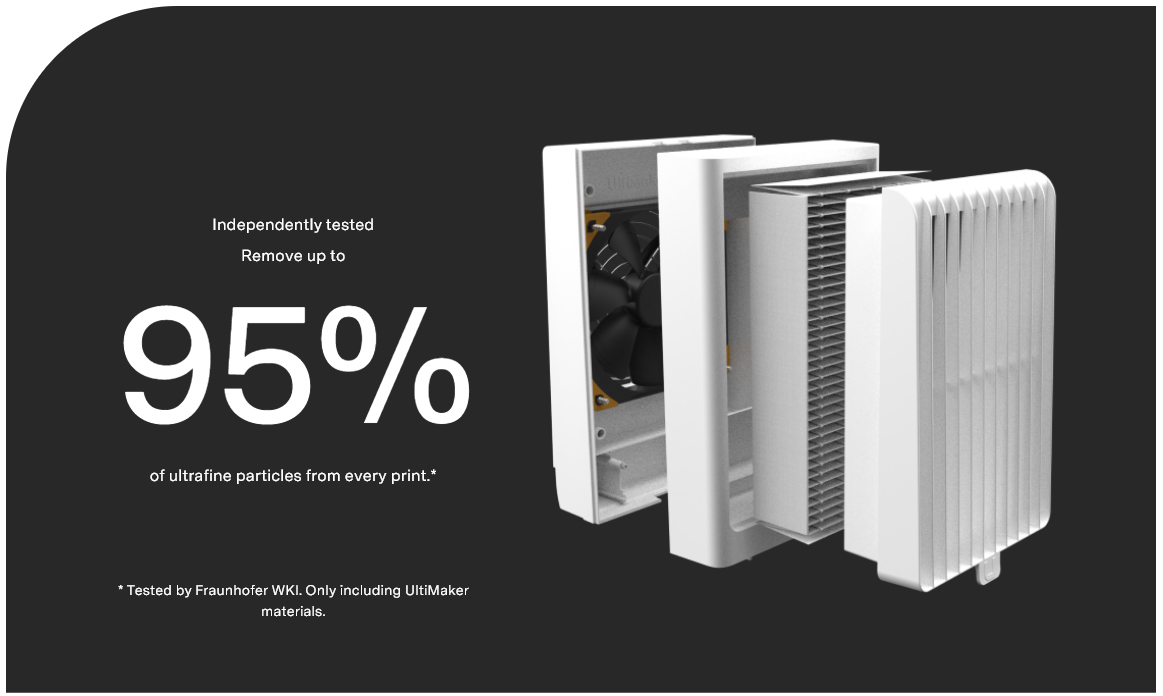

Easy printing. Easy breathing. |

Integrated Air ManagerNot only does this increase air quality peace of mind… It also boosts print quality thanks to its fully enclosed build chamber and single glass door. |

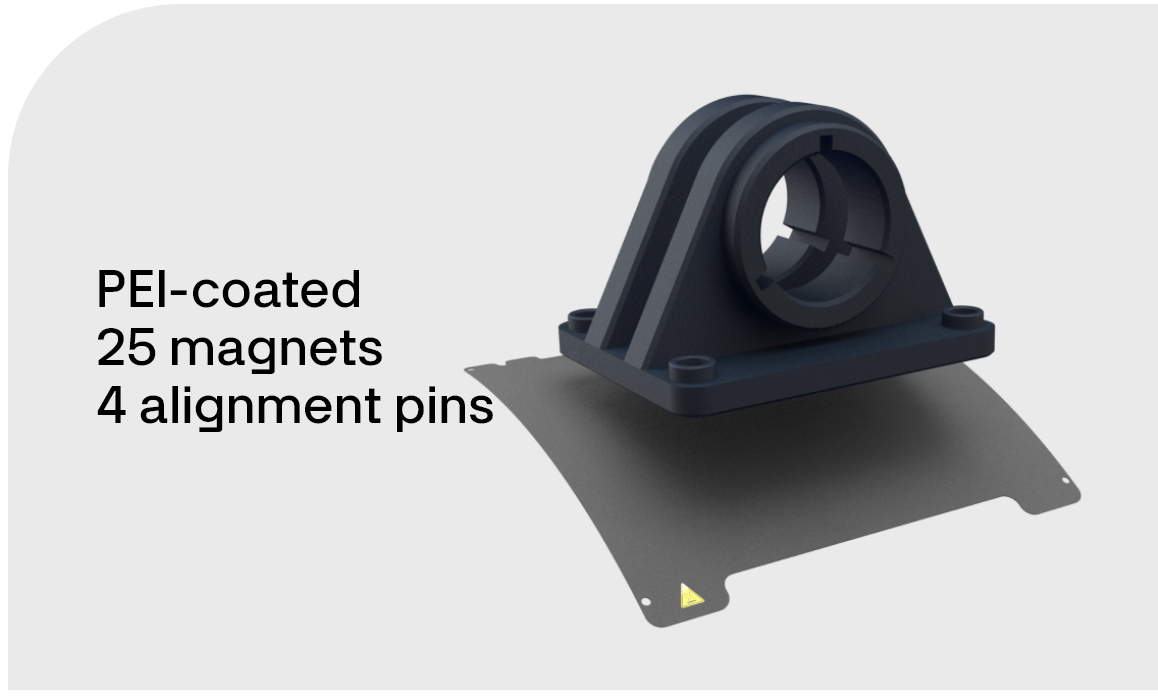

Skip using glue and remove parts effortlessly with the PEI-coated flexible build plate. Its patent-pending design uses 25 magnets and 4 pins for perfect alignment – reducing the time spent using the S7 and increasing productivity.

A new inductive print head sensor probes the build plate with less noise and more accuracy. And automatic tilt compensation removes the need for thumbscrew bed calibration. Together, these allow you to start a print and walk away – confident in a perfect first layer.

330 x 240 x 300 mm (13 x 9.4 x 11.8 inches)

W 495 x D 500 x H 1190 mm (W 19.5 x D 19.7 x H 46.9 inches)

Fused Deposition Modeling (FDM)

2.85 mm

41.9 kg (92.4 lbs)

500 W

0.25 mm nozzle: 150 - 60 micron 0.4 mm nozzle: 200 - 20 micron 0.6 mm nozzle: 300 - 20 micron 0.8 mm nozzle: 600 - 20 micron

6.9, 6.9, 2.5 micron

Dual-geared feeder, reinforced for composite materials

4.7-inch (11.9 cm) color touchscreen

Swappable print cores

Dual extrusion print head with an auto-nozzle lifting system, swappable print cores, and flood detection.

0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm

Replaceable EPA filter

1 - 50 m³/h (35 m³/h nominal rate for most materials at 23 °C)

180 - 280 °C

< 2 minutes

< 51 dBA

Advanced active leveling with more accurate inductive sensors

PEI-coated flexible steel build plate

< 5 minutes (from 20 to 60 °C)

15 - 32 °C (59 - 90 °F)

0 - 32 °C (32 - 90 °F)

UltiMaker Cura – print preparation software UltiMaker Digital Factory – printer management software UltiMaker Essentials – enterprise-grade online software tools

MacOS, Windows, and Linux

SolidWorks, Siemens NX, Autodesk Inventor

UltiMaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Printable formats: G, GCODE, GCODE.gz, UFP

Wi-Fi (2.4 and 5 GHz), Ethernet, USB

CE, FCC, VPAT, RoHS, REACH, CB, BIS, KC, PSE, RCM, SRRC, MIC, NCC, Safe unattended professional use

Learn more about UltiMaker S7 Pro Bundle safety and compliance.

No account yet?

Create an Account