News Letter

$20,526.32 Original price was: $20,526.32.$19,500.00Current price is: $19,500.00.

The UltiMaker Factor 4 is an industrial 3D printer built for the factory floor, with direct dual extrusion, automated material handling, and an actively heated, insulated build volume. It delivers highly repeatable, production-ready parts using engineering composites like PET CF and PPS CF, backed by onboard print process reporting and advanced environmental control for consistent results across batches and locations.

UltiMaker Factor 4 is an industrial 3D printer engineered for production environments where repeatability, uptime, and traceability matter. With a triple-insulated, actively heated build volume, direct dual extrusion, and automated material handling, Factor 4 streamlines the path from design to deployment and keeps operations running with minimal variation between parts.

This factory-ready system is built to create structural, production-grade components using advanced engineering materials and composites. From validated batch reporting to low-humidity material storage and onboard monitoring, UltiMaker Factor 4 gives manufacturers confidence in every print while integrating smoothly into existing workflows. Looking to compare systems? Browse all 3D printers and supplies from Paragon Visual.

| Highlight | Details |

|---|---|

| Built for the factory floor | The seamless, powerful upgrade that demanding production workflows require. Factor 4 elevates manufacturing with a triple-insulated build chamber, direct dual extrusion system, and automated material handling to maintain filament quality. Temperature-controlled design helps deliver consistent production output, even on complex and challenging parts. |

| Reliable and repeatable | Engineered to deliver high-quality results again and again, with tightly controlled print conditions and process monitoring that support consistent outcomes across the full build area and across multiple printers. |

| Advanced dual extrusion | The direct drive extrusion system allows you to move easily between flexible materials, standard engineering polymers, and carbon fiber-reinforced composites without sacrificing quality. |

Heavy duty, heavy weight direct dual extrusion for effective industrial 3D printing.

| Performance Focus | Description |

|---|---|

| High quality results anywhere | Factor 4 is designed to achieve tight dimensional accuracy and consistent mechanical behavior, print after print. With validated process control, it supports the production of structural parts that must perform reliably in real-world use. |

| Print completion success | The industrial design, closed-loop systems, and controlled environment support a high print completion rate, helping teams keep jobs on schedule and reduce wasted time and material. |

Hassle-free industrial 3D printing with a high print completion success rate.

| Capability | Description |

|---|---|

| Direct drive extrusion for flexible materials | The H-bridge gantry and direct drive print head in the UltiMaker Factor 4 enable rapid dual-material printing, allowing the system to move from highly flexible materials to strong composites like PET CF and PPS CF with confidence. |

| High-temperature capability | With the UltiMaker HT print core, Factor 4 can reach high nozzle temperatures to support advanced engineering materials while maintaining a controlled thermal environment around the part. |

High-temperature, direct drive dual extrusion supports a broad range of flexible and composite materials.

| Feature | Description |

|---|---|

| Success with every print | Factor 4 supports producing and deploying structural integrity–verified parts across different sites. Low variance in extrusion rates and mechanical properties batch after batch is enabled by the controlled chamber, closed-loop feed control, and uniform build plate temperature. |

| Actively controlled environment | The build volume is actively heated and controlled to a consistent temperature, keeping variation tight across the entire print area and helping sensitive materials perform as expected. |

Actively controlled build volume and heated bed help maintain consistent conditions for engineering materials.

| Value | Description |

|---|---|

| Versatility and fast ROI | Factor 4 is designed to deliver strong return on investment by supporting tooling, fixtures, prototypes, and end-use parts on one platform. Regular updates and a modular hardware design help extend the useful life of the system. |

| Serviceable, modular design | The printer’s modular build allows authorized service partners and support teams to replace key components quickly, minimizing downtime and keeping production on track. |

New industrial 3D printer, same proven UltiMaker ecosystem with Cura and Digital Factory.

| System Feature | Description |

|---|---|

| Integrated HEPA filtration | A built-in HEPA filter and enclosed build chamber help manage ultrafine particles, providing additional air quality peace of mind in office and factory environments. |

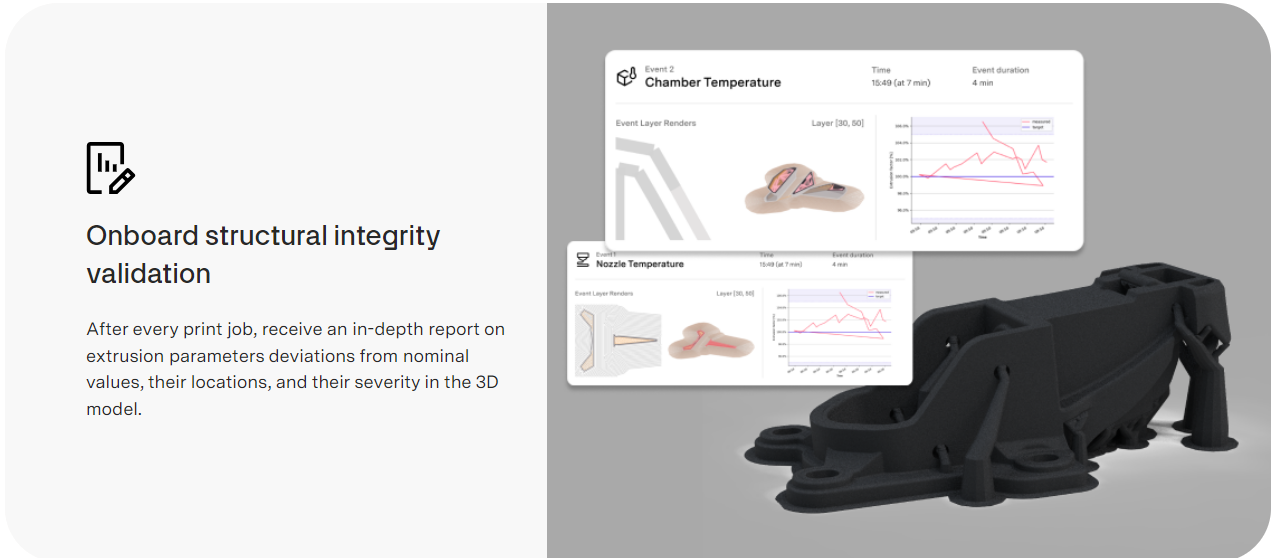

| Onboard structural integrity validation | After each print job, Factor 4 can report on extrusion parameter deviations and their locations within the part, helping teams evaluate consistency and traceability over time. |

| Automated material handling |  Material handling with low-humidity storage automatically pre-loads and switches spools, helping reduce manual intervention and keep long production jobs running smoothly. Material handling with low-humidity storage automatically pre-loads and switches spools, helping reduce manual intervention and keep long production jobs running smoothly. |

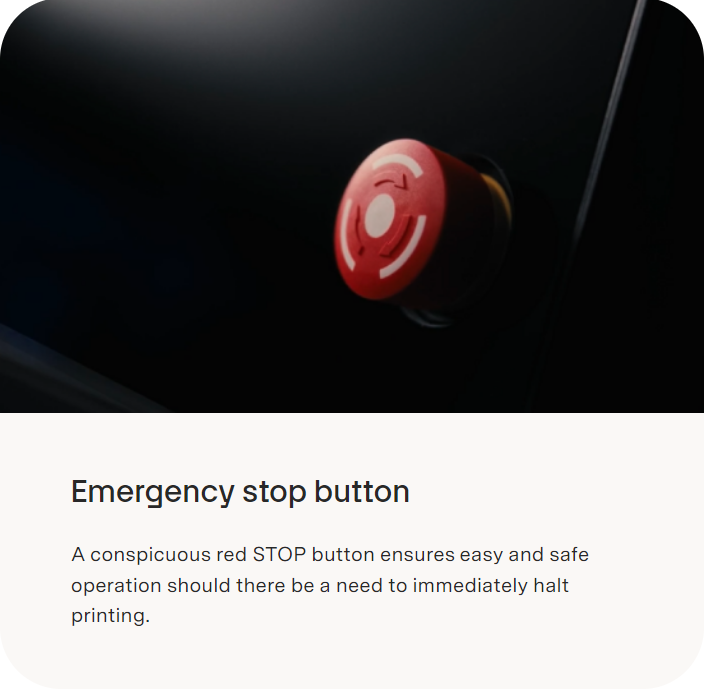

| Emergency stop for safety |  A prominent red emergency stop button allows operators to halt motion and extrusion immediately if needed, supporting safe use on the factory floor. A prominent red emergency stop button allows operators to halt motion and extrusion immediately if needed, supporting safe use on the factory floor. |

| Specification | Details |

|---|---|

| Printing Technology | Fused deposition modeling (FDM) with direct dual extrusion print head |

| Build Volume | Approx. 13.0 x 9.4 x 11.8 in (X x Y x Z) effective build area |

| Filament Diameter | Approx. 0.11 in nominal filament diameter |

| Compatible Print Cores | UltiMaker AA, BB, CC, DD, and HT print cores (including high-temperature HT core) |

| Max Nozzle Temperature | Up to 644 °F with the HT print core |

| Build Plate | Flexible PEI-coated build plate, heated up to approx. 248 °F |

| Actively Heated Chamber | Actively controlled build volume up to approx. 158 °F for consistent print conditions |

| Material Handling System | Integrated system with six bays for spools (around 2.2 lb each) with low-humidity storage for dependable feeding |

| Filtration | Integrated HEPA system with recirculating air and dedicated cooling fans |

| Connectivity | Wi-Fi (2.4 / 5 GHz), Gigabit Ethernet (LAN), and USB |

| Monitoring | Full HD HDR monitoring camera plus onboard reporting tools |

| Display | Color touchscreen interface for setup and control |

| Exterior Dimensions | Approx. 51 x 24 x 27.5 in (W x D x H) |

| Approximate Weight | About 265 lb |

| Operating Noise | Under 50 dBA in typical operating conditions |

UltiMaker Factor 4 – the industrial 3D printer built to keep your factory running, with repeatable parts, advanced materials, and process insight you can trust.

UltiMaker 3D printers from Paragon Visual give you a secure, supported path into professional additive manufacturing – from your first prototype to full production.

330 x 240 x 300 mm (13 x 9.4 x 11.8 inches)

695 x 605 x 1287 mm (27.5 x 24 x 51 inches)

Fused Deposition Modeling (FDM)

2.85 mm

120 kg (265 lbs)

600 W

0.25 mm nozzle: 150 - 60 micron 0.4 mm nozzle: 200 - 20 micron 0.6 mm nozzle: 300 - 20 micron 0.8 mm nozzle: 600 - 20 micron

6.9, 6.9, 2.5 micron

Dual-extrusion, direct drive print head and swappable print cores

7 inches interactive touchscreen (resolution 1024 × 600 px)

Swappable print cores

Dual extrusion print head with an auto-nozzle lifting system, swappable print cores, and flood detection.

0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm

Replaceable HEPA H13 filter

180 - 340 °C

PEI-coated flexible steel build plate

18 - 30 °C (64 – 86 °F) , Humidity: 30 – 70% RH

5° – 40 ºC (41 – 104 °F) , Humidity: 20 – 90% RH

UltiMaker Cura – print preparation software UltiMaker Digital Factory – printer management software

MacOS, Windows, and Linux

SolidWorks, Siemens NX, Autodesk Inventor

UltiMaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Printable formats: G, GCODE, GCODE.gz, UFP

Wi-Fi (2.4 and 5 GHz), Ethernet, USB

Learn more about UltiMaker Factor 4 safety and compliance.

Red Stop Button for motion & heat sources immediate stop Open Door Sensor for motion and extrusion pausing.

12 months Limited Warranty

No account yet?

Create an Account