News Letter

$349.00

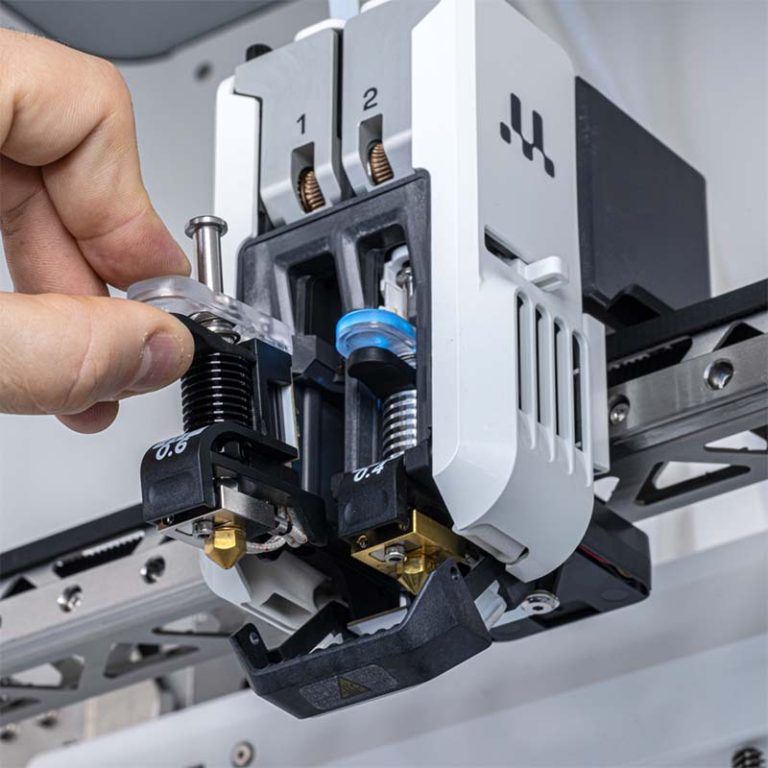

The UltiMaker HT print core 0.6mm is designed exclusively for the UltiMaker Factor 4, enabling high-temperature, composite-ready 3D printing. With nozzle temps up to approximately 644 °F, this abrasion-resistant core is ideal for PPS CF and other engineering-grade materials, delivering durable, heat-resistant parts for demanding industrial applications.

UltiMaker HT print core in the 0.6mm size is engineered specifically for the UltiMaker Factor 4 industrial 3D printer. Designed for high-temperature, composite-ready performance, this hardened print core allows you to print engineering-grade materials at nozzle temperatures up to approximately 644 °F. It is ideal for demanding applications where heat resistance, strength, and reliability matter.

With an abrasion-resistant construction and Factor 4–specific compatibility, the UltiMaker HT print core is optimized for high-performance composites such as PPS CF and other advanced materials that require elevated extrusion temperatures and stable thermal control. When combined with UltiMaker Cura and the Factor 4 ecosystem, it delivers predictable, repeatable results for production-grade parts and manufacturing aids.

| Specification | Details |

|---|---|

| Nozzle Diameter | 0.6mm (approx. 0.024 in) |

| Maximum Nozzle Temperature | Up to approximately 644 °F |

| Print Core Type | HT (high-temperature, abrasion-resistant) |

| Recommended Materials | High-temperature and composite materials such as PPS CF and other engineering-grade filaments |

| Printer Compatibility | UltiMaker Factor 4 only |

Enhance your UltiMaker Factor 4 with the HT Print Core 0.6mm and unlock high-temperature, composite-ready 3D printing for robust, heat-resistant industrial parts.

UltiMaker 3D printers from Paragon Visual give you a secure, supported path into professional additive manufacturing – from your first prototype to full production.

No account yet?

Create an Account