Streamlining Production with 3D Printed Guide Rails in Packaging

In high-speed manufacturing, even the smallest part can have a massive impact. One such example? Guide rails used in bottle packaging lines. These seemingly simple components play a critical role in keeping production moving smoothly—and now, 3D printing is transforming how they’re made.

At Paragon Visual, we’re seeing firsthand how additive manufacturing is enabling faster, more flexible solutions across industries. A perfect example comes from a recent case study featured by Ultimaker, where 3D printed guide rails helped streamline production in a hygiene product bottling facility.

Why Guide Rails Matter

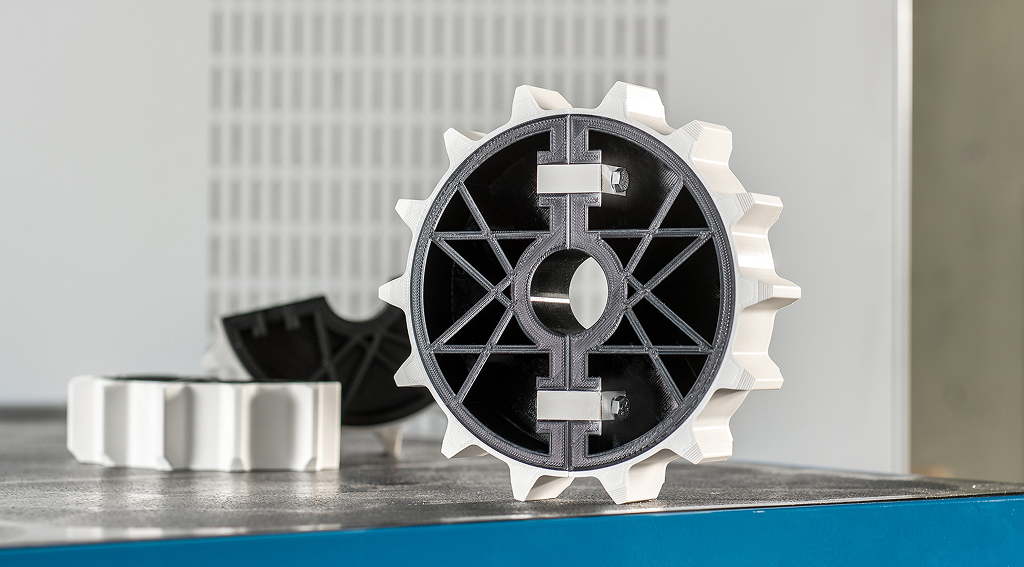

Guide rails are used on conveyor lines to keep bottles in position as they move through the packaging process. Traditional manufacturing methods require custom rails to be machined—often with long lead times and high costs. When a new bottle shape is introduced or production changes, replacing or modifying these rails can delay output.

3D Printing to the Rescue

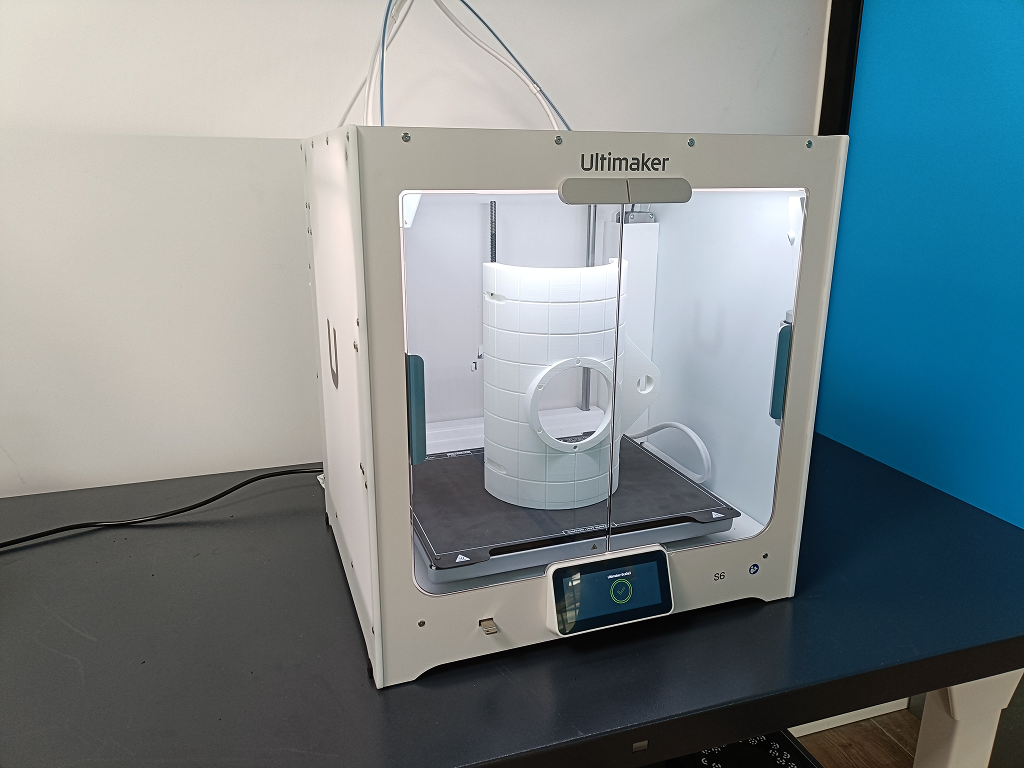

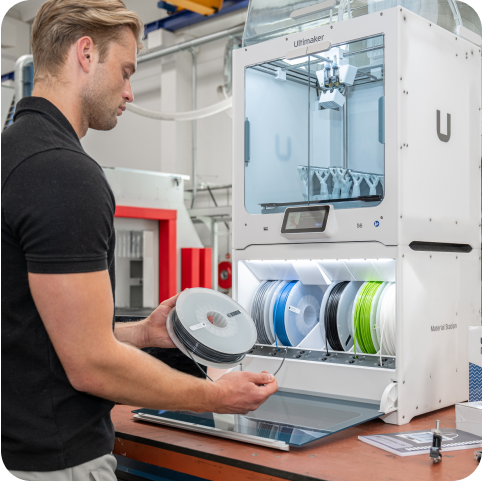

With industrial 3D printers like the UltiMaker Factor 4, guide rails can be printed in-house using high-strength polymers. Here’s what that means for your operations:

- 🕒 Rapid Turnaround: Print replacement rails in hours—not weeks.

- 💡 Customization: Adjust dimensions and designs on the fly to fit new product lines.

- 💰 Cost Savings: Eliminate expensive CNC machining or outsourcing.

- ♻️ Sustainability: Minimize waste by producing only what you need, when you need it.

Real-World Results

In the Ultimaker case study, a packaging company 3D printed custom guide rails tailored to a new hygiene product bottle. The result? Smooth bottle flow, reduced jams, and increased uptime—without waiting weeks for a new part.

This is the kind of agile solution that’s making 3D printing a must-have tool for manufacturers.

Is Your Line Ready for the Future?

If you’re managing high-throughput packaging or production systems, integrating 3D printing into your workflow can unlock massive efficiencies. Whether it’s custom rails, jigs, fixtures, or tooling—we can help you find the right printer and material for the job.

Explore our industrial 3D printer lineup, including the UltiMaker Factor 4, and see how Paragon Visual supports manufacturers with tailored additive manufacturing solutions.

📩 Let’s talk about how 3D printing can improve your packaging lines.

UltiMaker Factor 4 – Industrial 3D Printer

The UltiMaker Factor 4 is an industrial 3D printer built for the factory floor, with direct dual extrusion, automated material handling, and an actively heated, insulated build volume. It delivers highly repeatable, production-ready parts using engineering composites like PET CF and PPS CF, backed by onboard print process reporting and advanced environmental control for consistent results across batches and locations.