News Letter

$12,734.74 Original price was: $12,734.74.$11,500.00Current price is: $11,500.00.

Introducing the UltiMaker S7. We took everything our customers love about the award-winning S5… And made it even better.

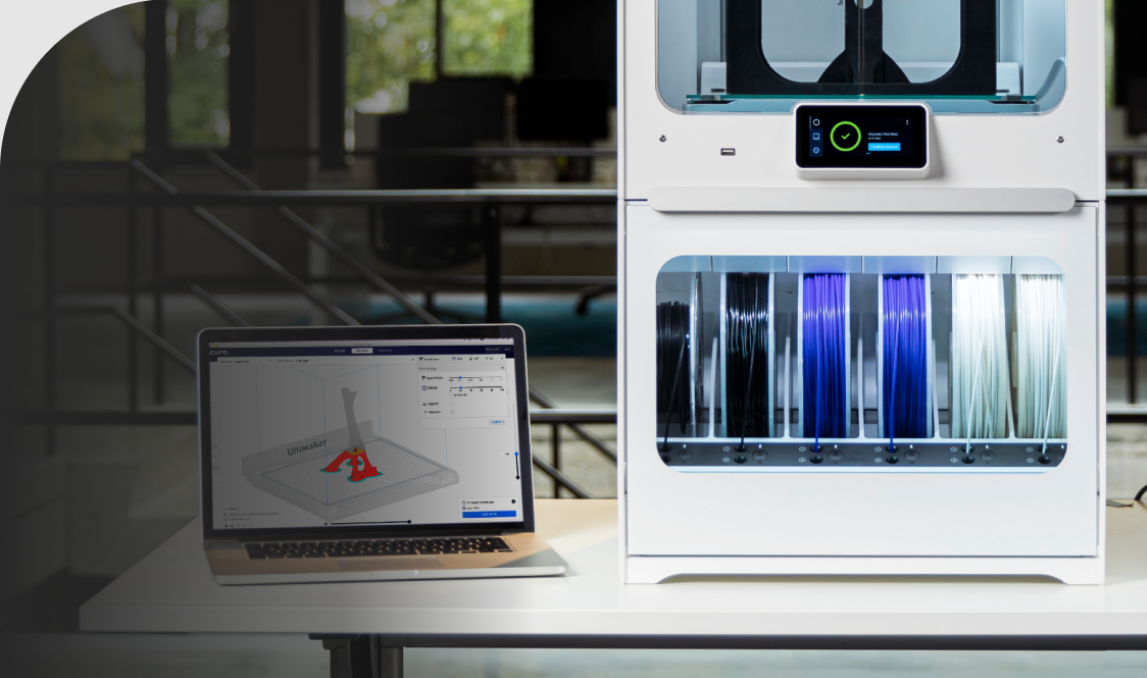

The UltiMaker S7 Pro Bundle adds the Material Station to our newest S series 3D printer, transforming it into a manufacturing powerhouse. This one-of-a-kind upgrade further simplifies the 3D printing workflow with automatic switching of up to 6 spools. And constant humidity control ensures material is delivered in perfect condition for high-quality 3D prints.

UltiMaker S7 Pro bundle combines the award-winning UltiMaker S7 3D printer with the Material Station and Air Manager to deliver nonstop, automated 3D printing. Designed for professional environments, this bundle keeps materials conditioned, filters ultrafine particles, and maximizes uptime so your team can focus on design, engineering, and production.

With a large build volume, flexible build plate, advanced active leveling, and seamless software integration, the UltiMaker S7 Pro bundle is ideal for functional prototypes, manufacturing aids, and low-volume production parts. Browse all 3D printers and supplies from Paragon Visual.

The UltiMaker S7 Pro bundle is built to run day and night with minimal operator intervention. Advanced active leveling, run-out and clog detection, and a fully enclosed build chamber help ensure successful prints, even on long, complex jobs. Load your files, choose your material, and let the system handle the rest.

The integrated Material Station turns the UltiMaker S7 into a true production workhorse. Designed to be left unattended, it allows the printer to 3D print longer – day or night. Loading material takes seconds: simply open the front door and drop each spool into a bay. Spools not in use can be swapped while a job is running, helping keep your UltiMaker S7 Pro bundle printing continuously.

Front-loading bays for six spools, including abrasive composites.

Every spool loaded into the Material Station is stored in a humidity-controlled environment, kept below 25% relative humidity. This helps reduce moisture-related print failures and makes it easier to realize more 3D printing applications with a wide range of polymers and abrasive composites. Each bay includes NFC readers and reinforced prefeeders for deep integration with UltiMaker Cura and Digital Factory. Learn more about UltiMaker Cura software.

Materials automatically kept in a dry, controlled environment.

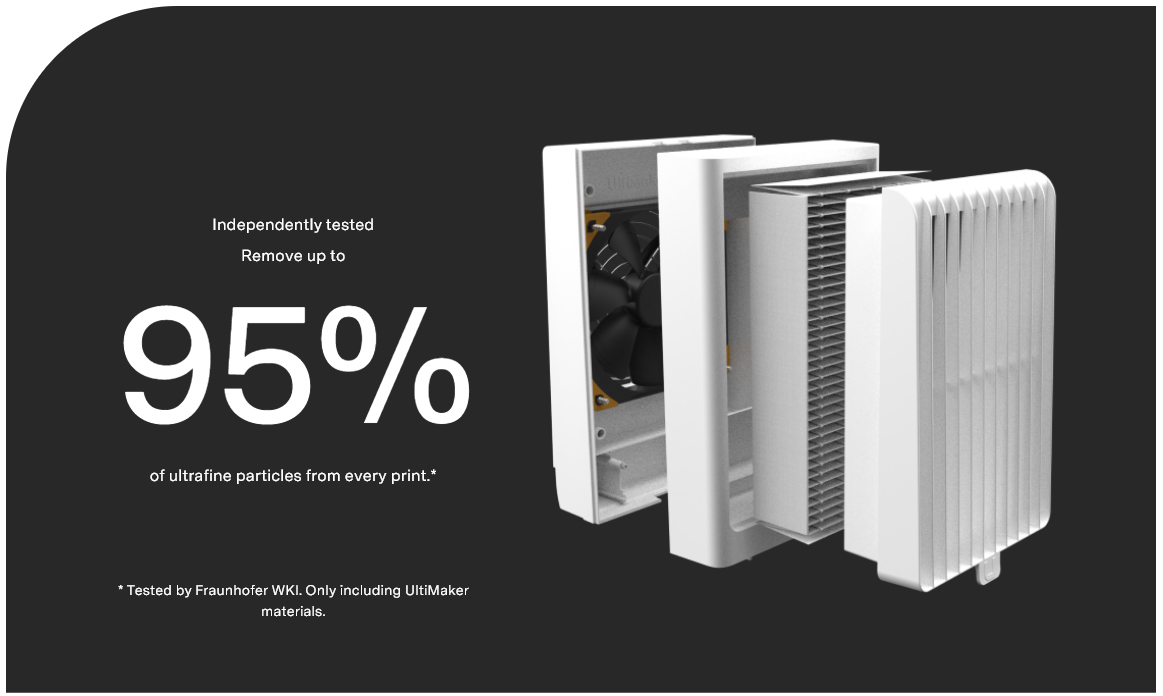

The Air Manager fully encloses the build chamber and pulls air through a high-efficiency filter, giving you added peace of mind in offices, labs, and classrooms. It helps capture ultrafine particles while also regulating the internal temperature of the build area. This not only improves air quality confidence, it also supports more consistent print quality from part to part.

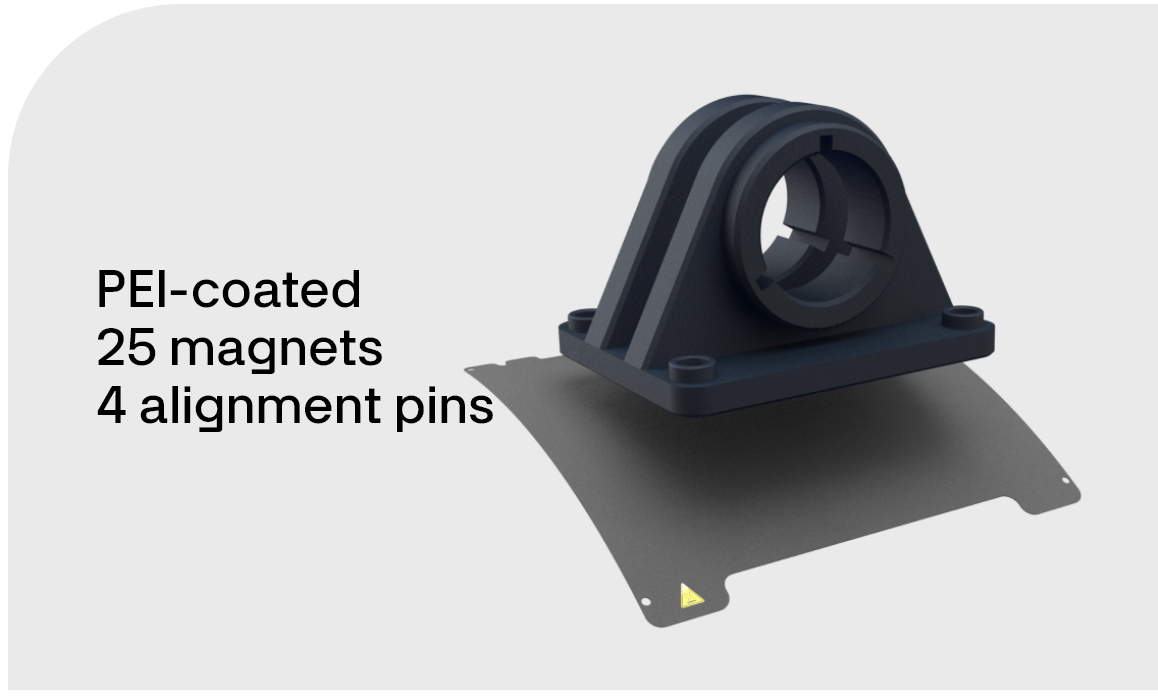

The PEI-coated flexible build plate makes print removal faster and easier. Skip messy glue and simply flex the plate to release parts after printing. A patent-pending design uses a grid of magnets and alignment pins to lock the plate in place, helping ensure consistent positioning and reducing time spent on setup.

An inductive print head sensor probes the build plate with greater accuracy and less noise than traditional systems. Automatic tilt compensation removes the need for manual thumbscrew calibration. Together, these features help the UltiMaker S7 Pro bundle deliver a reliable first layer so you can start a print and walk away with confidence.

| Specification | Details |

|---|---|

| Technology | Fused filament fabrication (FFF) dual-extrusion system |

| Build Volume (S7) | 13 × 9.4 × 11.8 in |

| Build Plate | PEI-coated flexible build plate, heated up to 284 °F |

| Active Leveling | Inductive build plate sensor with automatic tilt compensation |

| Air Manager | Integrated enclosure and filter for ultrafine particles and thermal control |

| Connectivity | Wi-Fi (2.4/5 GHz), LAN, USB; integrated with UltiMaker Digital Factory |

| Sound Level | Under 50 dBA during operation |

| Printer Dimensions | Approx. 19.5 × 23 × 31.5 in (including spool holder) |

| Printer Weight | Approx. 64 lb |

| Compatible Materials | Wide range of standard and advanced materials, including PLA, Tough PLA, PETG, ABS, PC, CPE, Nylon, PP, TPU 95A, composites, and soluble supports. |

The UltiMaker S7 Pro bundle gives you all the uptime, reliability, and automation you need to scale professional 3D printing with confidence.

UltiMaker 3D printers from Paragon Visual give you a secure, supported path into professional additive manufacturing – from your first prototype to full production.

330 x 240 x 300 mm (13 x 9.4 x 11.8 inches)

W 495 x D 500 x H 1190 mm (W 19.5 x D 19.7 x H 46.9 inches)

Fused Deposition Modeling (FDM)

2.85 mm

41.9 kg (92.4 lbs)

500 W

0.25 mm nozzle: 150 - 60 micron 0.4 mm nozzle: 200 - 20 micron 0.6 mm nozzle: 300 - 20 micron 0.8 mm nozzle: 600 - 20 micron

6.9, 6.9, 2.5 micron

Dual-geared feeder, reinforced for composite materials

4.7-inch (11.9 cm) color touchscreen

Swappable print cores

Dual extrusion print head with an auto-nozzle lifting system, swappable print cores, and flood detection.

0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm

Replaceable EPA filter

1 - 50 m³/h (35 m³/h nominal rate for most materials at 23 °C)

180 - 280 °C

< 2 minutes

< 51 dBA

Advanced active leveling with more accurate inductive sensors

PEI-coated flexible steel build plate

< 5 minutes (from 20 to 60 °C)

15 - 32 °C (59 - 90 °F)

0 - 32 °C (32 - 90 °F)

UltiMaker Cura – print preparation software UltiMaker Digital Factory – printer management software UltiMaker Essentials – enterprise-grade online software tools

MacOS, Windows, and Linux

SolidWorks, Siemens NX, Autodesk Inventor

UltiMaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Printable formats: G, GCODE, GCODE.gz, UFP

Wi-Fi (2.4 and 5 GHz), Ethernet, USB

CE, FCC, VPAT, RoHS, REACH, CB, BIS, KC, PSE, RCM, SRRC, MIC, NCC, Safe unattended professional use

Learn more about UltiMaker S7 Pro Bundle safety and compliance.

No account yet?

Create an Account