3D Printing in Action: Custom Drone Bracket Enhances Life-Saving Tech

At Paragon Visual, we love spotlighting how real-world 3D printing applications are driving innovation across industries. This week, we’re excited to share an impressive project where a custom-designed drone bracket was developed using the UltiMaker S6 and PET CF filament — demonstrating just how effective additive manufacturing can be when paired with the right tools.

The part was produced entirely in-house and designed to support humanitarian efforts in mine detection using advanced drone imaging systems.

Mission-Ready: Lightweight and Functional

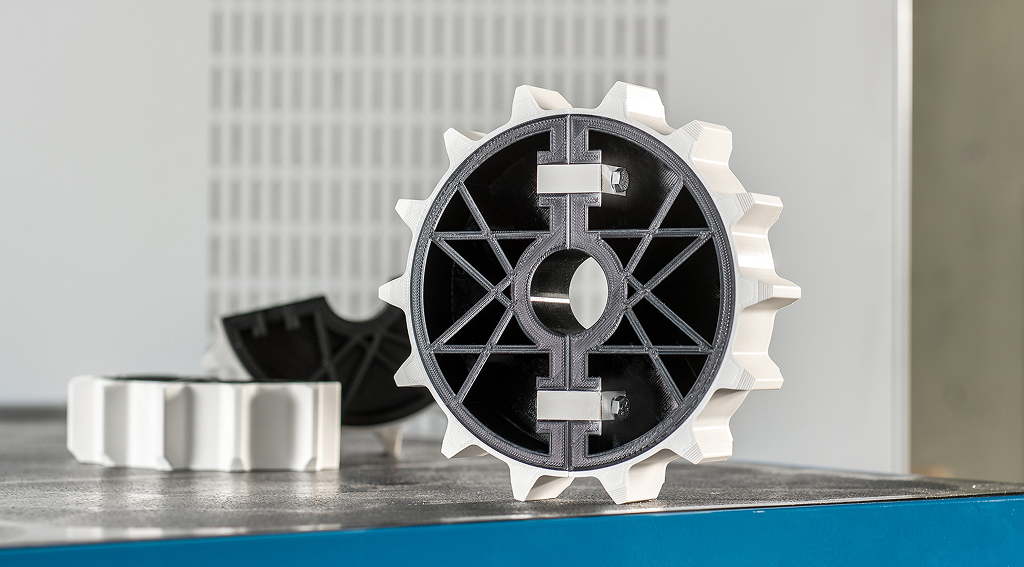

The challenge was to create a drone-mounted bracket capable of securing both thermal and RGB cameras used to scan for plastic landmines in conflict zones. This dual-purpose camera system required:

- A snug, secure mount

- Low overall weight to maximize flight time

- High durability for field conditions

Every element of the bracket’s geometry was optimized using UltiMaker Cura, the industry-leading slicing software that offers advanced controls for material usage, infill, wall thickness, and support structures.

UltiMaker S6 + PET CF = Professional Performance

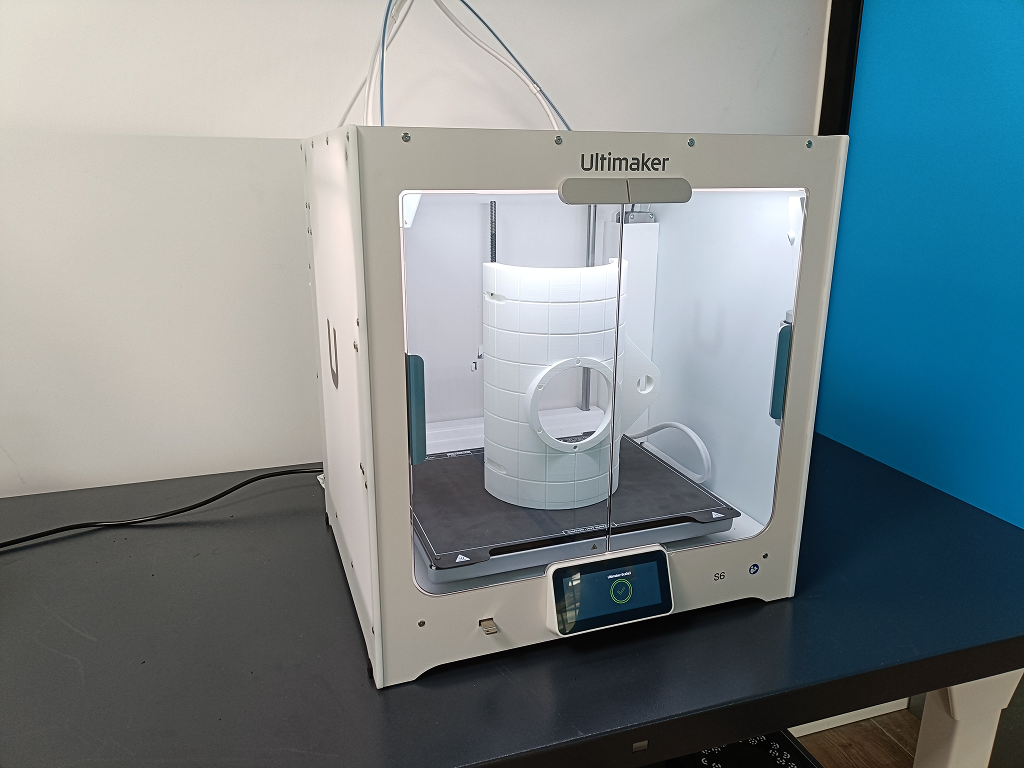

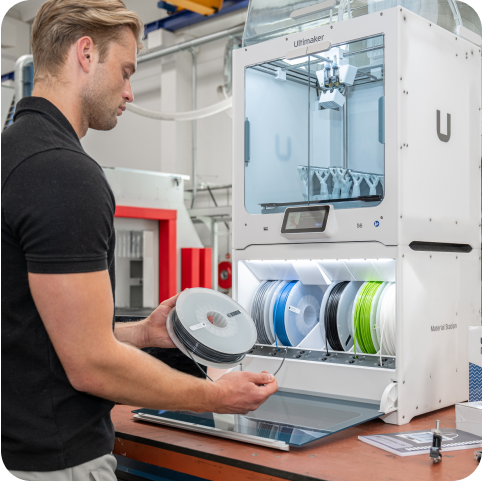

The bracket was 3D printed using the UltiMaker S6, a dual-extrusion professional printer ideal for complex mechanical parts and functional prototypes. To ensure strength without adding weight, the team used PET CF — a carbon fiber-reinforced filament with high rigidity, temperature resistance, and dimensional stability.

The final part included:

- A robust frame to mount the cameras

- A protective cover plate to shield delicate electronics

- Clean interfaces and tolerances for easy integration

Cura Optimization: From 10 Hours to 3 Hours Print Time

Using UltiMaker Cura, the team was able to reduce the total print time from over 10 hours to just 3 hours and 12 minutes — a 65% improvement without compromising structural quality.

Advanced slicing techniques allowed them to:

- Adjust wall and infill settings for optimal strength

- Use support strategies that minimized post-processing

- Maintain dimensional accuracy and smooth surface finish

The UltiMaker S6’s precision print bed and closed front enclosure further ensured that the carbon fiber filament performed reliably across multiple print cycles.

Why This Application Stands Out

This project showcases the best of what’s possible when you combine professional-grade 3D printing hardware, high-performance materials, and expert design practices:

- Over 65% faster print time with Cura slicing

- Carbon fiber strength with lightweight PET CF

- Precision camera mounting for aerial image accuracy

- No tooling or outsourcing — made entirely in-house

- Ready for field use in demanding, life-saving missions

Ready to Build Smarter? Let’s Talk.

At Paragon Visual, we support professionals in aerospace, education, manufacturing, and defense with 3D printing solutions that help you move faster and smarter.

Looking to explore functional printing, optimize workflows, or bring your prototyping in-house? The UltiMaker S6, paired with materials like PET CF, offers the power and precision to take your ideas from sketch to sky.

👉 Explore UltiMaker 3D printers »

👉 Need help choosing the right printer or material? Talk to our team »

Source: Adapted from Ultimaker. Original article available here