News Letter

If your organization prints plan sets, CAD drawings, posters, or everyday visuals, you already know the truth: printing should be the easiest part of the job. The HP DesignJet T870 printer platform (including the XT870 variant) is built for teams that need reliable, professional wide format output without constant babysitting, bottlenecks, or reprints.

This matters most for architects, engineers, schools, universities, and corporate print environments where multiple users send jobs all day and deadlines do not politely wait their turn. The right printer is not just about image quality. It is about workflow. It is about repeatability. It is about helping your team move from “print request” to “in hand” with less friction.

Wide format printing should be a tool, not a time sink.

Most “printing problems” are not really print quality problems. They are workflow problems. The pain usually shows up as:

The HP DesignJet T870 printer family is built to reduce those issues in real production environments, especially when your team prints a mix of technical documents and graphic content.

Multi size output is where many offices get stuck. A typical day might include full size plans, half size sets for review, and smaller sheets for markups or handouts. When a printer setup forces constant media changes, the workflow slows down and errors creep in.

The T870 and XT870 approach is to support practical office printing where teams can produce different sizes confidently, with fewer interruptions. That keeps projects moving, reduces reprints, and helps the print area stay predictable even with multiple users.

If you want the specifics on the model you are offering, your product page is here:

HP DesignJet XT870 printer.

A wide format printer has to do two jobs well: produce clean technical linework and deliver strong, professional visuals. For technical documents, the goal is simple: crisp lines, readable small text, and consistent output from sheet to sheet. For posters and signage, you want clean color, solid fills, and output that looks finished when it hits the wall.

This is why the T870 platform fits environments like:

Speed is great, but speed without control just makes mistakes happen faster. The real productivity win comes from workflow tools that help users submit jobs correctly the first time. Preview before printing, consistent settings, and fewer “mystery results” are what reduce waste and keep teams confident.

For busy offices, the best wide format workflow is the one that feels simple enough for everyone to use, not just the one person who “knows the printer.”

In the real world, wide format printers are shared. That means the printer must support collaborative use across departments, classrooms, and teams. It also means security matters, especially in engineering, government adjacent work, and corporate environments where plans and internal documents should not be treated casually.

If your organization has security requirements or internal policies, we can help you match the right configuration and best practices to keep printing productive without creating unnecessary risk.

Nothing sells the story like seeing what the output looks like in the environments people actually work in. Here are a few examples that match how schools and retail spaces use wide format prints every day.

Education example: classroom learning visuals and wall posters.

Education example: event posters and hallway signage.

Retail example: promotional posters and point of sale graphics.

Retail example: cafe promos, seasonal campaigns, and wall graphics.

If you want to see the printer in action and get a feel for how it fits into a real workflow, here is the video:

A wide format printer is only as useful as the support behind it. Paragon helps organizations choose the right solution, set it up correctly, and keep it running the way it should. If you are replacing an older machine, expanding capacity, or standardizing printing across a department, we can guide the process and keep it simple.

Helpful next steps:

If your organization prefers a clear recycling path for used supplies, HP provides recycling options through HP Planet Partners. Details here:

HP ink and toner recycling

The HP DesignJet T870 printer platform is a strong match for teams that need fast, dependable wide format printing across multiple use cases. From CAD drawings and technical documents to posters, classroom visuals, and retail graphics, it is built to reduce workflow friction and help teams stay on schedule.

If you want a quick sanity check before buying, send us a few details about your workflow: what you print, your typical sizes, and how many people use the printer. We will help confirm the best fit and the right configuration.

Tags:

If you’re exploring additive manufacturing for functional prototypes, jigs, fixtures, and real-world production aids, material choice matters just as much as the printer. UltiMaker PET CF filament is a carbon fiber composite designed for teams that want high stiffness, reliable print quality, and a smoother day-to-day experience than many other carbon fiber materials.

I’m not an engineer by trade, but I work with customers who are. This post is written for practical decision-making: what PET CF is, how it compares to other composites like PA CF, what you gain (and give up), and how to get consistent results on UltiMaker S Series and Factor 4 systems.

Shop UltiMaker PET CF here:

UltiMaker PET CF (S Series and Factor 4)

Browse printers and supplies:

3D printers and supplies

UltiMaker PET CF is a carbon fiber-reinforced version of PET (polyethylene terephthalate). In plain terms: it aims to deliver composite-level stiffness and stability, while keeping printing behavior closer to the “it just works” feel many people associate with materials like PETG.

UltiMaker positions PET CF as a go-to composite for industrial environments because it balances performance with reliability. That matters if you’re evaluating AM for real workflows, not just “cool demo parts.”

A common comparison is PET CF vs PA CF (nylon carbon fiber). Here’s the practical buyer-friendly version:

The takeaway: if your priority is stiffness, clean print quality, and consistency, PET CF is often the smoother path. If your priority is toughness and impact resistance, you may consider other engineering materials depending on the application.

“Stiffness” can sound abstract until you connect it to use cases. Stiffer materials resist bending. That’s valuable when parts need to hold shape under load, maintain alignment, or act like a stable tool.

UltiMaker notes PET CF reaches very high stiffness in the plane where fibers are oriented, which is exactly why it shines in fixtures and tooling-style prints.

Annealing is the “level up” option with PET CF. It’s a controlled heat treatment after printing that can significantly improve performance, especially temperature resistance.

UltiMaker provides annealing intent profiles in Cura to help compensate for typical shrinkage and keep parts dimensionally accurate. If your use case includes heat exposure, annealing can be a big reason PET CF ends up on the short list.

Official annealing instructions:

UltiMaker PET CF annealing instructions

PET CF is an abrasive composite, so it needs a printer platform built for that. UltiMaker notes PET CF is intended for Factor 4 and S Series printers that are prepared for abrasive materials, using abrasion-resistant print cores (such as CC, CC+, or HT options depending on the system).

Official “how to print” guidance:

How to print with UltiMaker PET CF

Here are the tips that tend to move PET CF from “we tried it once” to “we rely on it weekly.”

The point is not perfection. The point is repeatability. That’s what makes AM valuable for prototyping and production aids.

PET CF is excellent, but it’s not the answer to every application. Consider alternatives when:

That doesn’t mean “don’t use PET CF.” It means: match the material to the job, and you’ll win.

If you’re evaluating AM for prototyping or functional parts, we can help you narrow down the right printer and material combo based on what you’re actually making. No pressure, no jargon overload, just practical guidance.

Product page:

UltiMaker PET CF filament

Browse:

3D printers and supplies

UltiMaker PET CF filament is a strong option for teams who want carbon fiber stiffness with a reliable printing experience. It’s especially compelling for functional prototypes, fixtures, and manufacturing aids where dimensional stability matters. And if your application involves heat exposure, annealing can unlock a major jump in temperature resistance.

If you tell us what you’re making and what environment it will live in, we’ll help you decide whether PET CF is the right fit and which UltiMaker platform makes the most sense for your workflow.

Tags:

If you’ve ever compared 2 prints side by side and wondered why one looks crisp and vibrant while the other looks a little flat, you’re not imagining it. A lot of the time, the difference comes down to coated vs uncoated paper. This guide explains what each one is, how it affects print quality, and how to choose the best option for CAD drawings, plan sets, posters, and presentation graphics across architecture, engineering, reprographics, in-plant print rooms, and schools.

Quick truth: neither option is “always better.” Uncoated is the classic workhorse. Coated is the sharp dressed option when the print needs to impress. The trick is matching the paper to the job so you get the look you want without overspending.

Uncoated paper (often called bond paper) does not have an ink-receiving coating. Ink absorbs into the paper fibers, which is great for speed and cost control, and usually ideal for high volume CAD and technical printing.

Coated paper has a specially engineered surface layer designed to control how ink lands and dries. Because more ink stays near the surface, coated papers often deliver sharper detail, smoother fills, and richer color saturation. This is why coated stocks are common for presentation graphics and color-heavy prints.

Here’s what changes in the real world when you switch between coated vs uncoated paper:

Choose uncoated bond when readability, speed, and cost control matter most. This is the standard choice for many architecture and engineering teams printing day-to-day plan sets and reviews.

Browse uncoated options here: Bond Paper

Choose coated paper when the print needs to look finished. If the print is client facing, presentation focused, or color heavy, coated paper usually delivers a noticeably more polished result.

Browse coated options here: Coated Bond Paper

If you want a simple rule of thumb:

Will coated paper fix banding or printer issues? Coated paper can improve how ink looks on the page, but it will not fix a mechanical or ink delivery issue. If output quality is inconsistent across different media, it’s usually worth checking maintenance and print settings. Does uncoated always mean “lower quality”? Not at all. Uncoated bond is often the correct professional choice for technical drawings and high volume production. It’s “lower cost,” not “lower purpose.” Can schools use the same decision guide? Yes. For classroom posters or hallway graphics, coated matte is usually the nicer looking option. For everyday CAD style drawings, STEM projects, and drafts, uncoated bond is often the practical pick.

Picking paper sounds simple until you’re staring at a cart full of options and thinking, “Why are there 14 versions of something that is basically… paper?” That’s where we come in.

If you want a deeper dive, here’s a related resource: CAD and Engineering Papers: What Is the Best Fit for You?

Need a recommendation for your specific workflow? Reach out and we’ll point you in the right direction. Contact Paragon Visual

The coated vs uncoated paper choice comes down to one question: is this print mainly functional, or does it need to impress? For daily CAD and plan sets, uncoated bond is hard to beat. For color-heavy output and presentation work, coated papers typically deliver the richer, sharper look people expect.

Tags:

HP DesignJet Cash In & Trade Up is back. Get up to $1,200 cash back.

Now through March 31, 2026, HP is rewarding you for upgrading your wide-format printer. Trade in your old qualifying inkjet or LED printer and receive up to $1,200 back when you purchase or lease an eligible new HP DesignJet model.

If your trusty old plotter has “earned its retirement,” this is one of the easiest ways to step into faster printing, better security, and cleaner output while lowering your net cost.

Whether you’re printing CAD drawings, GIS maps, retail graphics, posters, backlit, or photo-quality visuals, there’s an HP DesignJet built for the job.

Even better: When you buy through Paragon, we will handle the rebate claim process for you. No portals. No guessing. We’ll gather what’s needed and submit everything properly.

Tip: Each claim must include proof of purchase, so keep that invoice handy.

Here are the primary qualifying models and cash back amounts for the January–March 2026 promotion:

| Printer | Cash Back |

| HP DesignJet Z9+ Pro 64-inch Printer (2RM82A#B1K / 2RM82F#B1K) | $1,200 |

| HP DesignJet Z6 Pro 64-inch Printer (2QU25A#B1K / 2QU25F#B1K) | $550 |

| HP DesignJet T2600dr 36-inch PostScript® MFP (3EK15A#B1K) | $800 |

| HP DesignJet T2600 36-inch PostScript® MFP (3XB78A#B1K) | $600 |

| HP DesignJet T1600dr 36-inch PostScript® Printer (3EK13A#B1K) | $300 |

| HP DesignJet T1600 36-inch PostScript® Printer (3EK11A#B1K) | $400 |

| HP DesignJet T1600 36-inch Printer (3EK10A#B1K) | $400 |

Wondering if your current printer qualifies as a trade in? HP accepts a wide range of large-format inkjet and LED printers, including many legacy HP DesignJet models and competing brands.

In general, qualifying trade-ins include many 36-inch or larger wide-format printers. That includes inkjet models (HP DesignJet, Canon imagePROGRAF, Epson, Xerox, Ricoh, and more) and LED based systems (KIP, PlotWave, ColorWave, and others).

Buying a printer is easy. Buying the right printer and having it run like it should on day 1 is the part that matters. We help you:

🌎 Recycle your old printer responsibly with HP Planet Partners »

Ready to upgrade? Contact us and we will help you confirm eligibility, select the right model, and get you a quote. If you purchase through Paragon, we will also take care of the rebate claim submission.

See all our printers: Learn More

Tags:

High tack adhesive vinyl is what you reach for when a normal “permanent” decal just will not stay put. If you have graphics lifting on garbage and recycling carts, warning labels sliding off drums, or decals curling on powder-coated equipment, the problem usually is not the printer. It is the surface. This is where the Jessup TenaciousTac® family gives wide-format print shops a reliable way to keep graphics in place on tough substrates.

This article is written for shops running eco-solvent, solvent, latex or UV printers that need permanent graphics on low surface energy plastics, powder-coated metals and other problem surfaces. We will look at when to use high tack adhesive vinyl, where standard films fail, and how to choose the right Jessup TenaciousTac construction for each job.

Most everyday sign and label films use a standard permanent adhesive. That works well on smooth, high-energy surfaces like glass, painted aluminum or finished sign panels. On low surface energy plastics and textured finishes, however, the adhesive cannot “wet out” the surface properly, so the decal never forms a strong bond.

High tack adhesive vinyl solves this by using a thicker, more aggressive adhesive system that is designed to bite into difficult substrates. The film may look similar to a standard calendered vinyl from the front, but the adhesive layer underneath is doing much more work. When chosen correctly, high tack films help reduce callbacks, reprints and on-site repair trips caused by failed graphics.

If you hear customers say, “Nothing sticks to this,” you are probably looking at one of these surfaces:

On these substrates, a standard vinyl may look fine on day one but start lifting at corners, bubbling or sliding after exposure to temperature changes, cleaning and handling. A properly selected high tack vinyl, installed on a clean surface with firm pressure, is designed to stay put.

Paragon Visual offers several Jessup TenaciousTac constructions so you can match the film to the job instead of forcing one product to do everything. Here is a quick, real-world guide to the main options:

| TenaciousTac Film | Best Fit |

|---|---|

| TenaciousTac 4 | Ultra-aggressive white vinyl for “nothing sticks” surfaces like rough plastics, textured containers and challenging outdoor assets. |

| TenaciousTac 1CR | White high tack vinyl for equipment labels, bins and LSE plastics where you want strong adhesion and chemical resistance. |

| TenaciousTac 1CRG | White high tack vinyl with air egress liner for easier, bubble-resistant installs on larger decals and panels. |

| TenaciousTac CLR 1CRAE | Clear high tack vinyl with air egress liner when you want the surface color to show through behind the graphic. |

| TenaciousTac 2CR | White high tack vinyl with a thicker adhesive layer for heavy-duty drum labels, chemical containers and outdoor bins. |

| TenaciousTac CLR 2CR | Clear version of 2CR for containers, generators and equipment where you want durable clear graphics on difficult surfaces. |

If you are unsure which film to use, a simple rule of thumb is to start with 1CR for general high tack labeling, move to 1CRG or CLR 1CRAE when installers want air egress, and step up to the 2CR constructions or TenaciousTac 4 when drums, carts or containers demand extra adhesive strength.

The right film is only part of the equation. A few small workflow habits can make high tack jobs more predictable and repeatable:

High tack adhesive vinyl is not just a specialty item to keep on the shelf “just in case.” It can be a proactive solution that strengthens relationships with your customers. Consider recommending TenaciousTac when:

Paragon Visual stocks a full range of Jessup adhesive coated films, including the TenaciousTac products highlighted in this guide. Our team works every day with wide-format print providers, in-plant operations and industrial customers who need dependable performance on real-world surfaces, not just test panels.

If you are facing a difficult application or want to standardize on a high tack adhesive vinyl for drums, carts or equipment labeling, we can help you match the right TenaciousTac film to your substrate, printer platform and environment.

Ready to tackle a stubborn surface or quote a new project that needs high-tack performance? Contact Paragon Visual to talk through your application or explore the full Jessup lineup on our Jessup brand page.

Tags:

Defense 3D printing helps maintenance teams keep aircraft, vehicles, and mission-critical systems ready to deploy. Instead of waiting weeks or months for a custom tool or replacement part, units can now produce what they need in hours. They can do this on base or even in the field. This shift is especially powerful for maintenance officers and contractors who constantly fight long lead times, aging tooling, and tight budgets.

Traditional maintenance workflows rely on long supply chains, specialist suppliers, and complex procurement steps. When one machine shop controls a unique wrench, cap, or fixture—or when the tool does not exist at all—downtime stretches and costs rise. Modern defense 3D printing workflows flip that model. Simple, user-friendly printers and engineering-grade materials let teams design, print, and deploy purpose-built tools on demand.

Across the U.S. military and allied forces, teams often use a two-level maintenance strategy. Field units handle line maintenance. Depots or specialist shops take on more complex work. The structure looks solid on paper. In practice, it breaks down when a unit needs a one-off tool or adapter that is not already on the shelf.

The Royal Netherlands Air Force (RNLAF) faced exactly these challenges across Chinook, Apache, NH90, and F-16 fleets. Their teams needed specialized adjustment tools, engine caps, and fixtures that either did not exist or cost far too much and took too long to arrive. Instead of accepting those delays, they brought industrial desktop 3D printers into their own maintenance workflow and started producing tools on site.

Modern systems like the UltiMaker Factor 4 and secure S-series printers suit defense environments very well. They stay compact and fully enclosed. Dual-material extrusion prints strong, accurate parts from carbon-fiber composites, nylons, and flexible polymers.

With these tools, defense organizations move critical maintenance capability closer to the point of need. They do it without adding a huge training or infrastructure burden.

One widely cited example involves a custom wrench used for maintaining an underwater transport system. Traditionally, a machine shop manufactured this tool in steel. The team waited about 12 weeks for delivery and paid roughly $1,300 per wrench. By shifting to a 3D printed design that uses carbon-fiber-reinforced PA CF10 and a tribological filament, engineers cut both time and cost dramatically.

| Quick Stats (Example) | Traditional Tooling | With Defense 3D Printing |

|---|---|---|

| Lead time for custom wrench | ≈ 12 weeks | ≈ 13 hours |

| Unit cost (example) | ≈ $1,300 | ≈ $30 |

| Cost reduction | — | Up to ~98% savings |

The 3D printed design also improves the tool itself. Two contrasting materials create visible abrasion as the wrench wears. Technicians can see when to replace it and avoid damage to the system it serves.

One of the biggest advantages of defense 3D printing is how accessible it has become. Maintenance teams do not need to become full-time CAD specialists to see value. Instead, they can rely on proven workflows and repeatable steps.

Together, digital catalogs, secure workflows, and user-friendly hardware turn defense 3D printing from a “cool experiment” into a reliable maintenance capability.

Each defense maintenance environment looks a little different. Some teams need rugged, deployable systems for field repair. Others need high-throughput printers on the factory floor. Paragon Visual works with government and defense buyers to match the right platform to the mission, including:

If you are already exploring how 3D printing for defense contractors fits into your strategy, a maintenance-focused pilot around tools and fixtures often delivers the fastest ROI.

For defense organizations, every day of downtime carries a cost: operational, financial, and strategic. When you bring defense 3D printing directly into maintenance workflows, you turn specialty tools and fixtures from a supply-chain liability into a local capability. The Royal Netherlands Air Force and other armed forces now print custom tools in hours instead of months and see cost reductions that approach 98% in some cases.

If you are ready to explore secure, TAA-compliant 3D printing that supports your maintenance and readiness goals, Paragon Visual can help. Our team supports platform selection, pilot programs, and long-term fleet support across the United States.

If you would like help evaluating platforms, materials, or a pilot workflow,

contact Paragon Visual. We support government and defense buyers across the United States.

Tags:

At Paragon Visual we make it simple to choose sustainability and performance together. The HP Planet Partners Recycling Program provides a free and easy way to return Original HP ink and toner cartridges. Returned materials are responsibly processed so plastics and metals can be used again in new HP products and in other useful items. When you recycle your cartridges you help reduce waste and support a circular approach to printing without giving up the consistent output that HP DesignJet users expect.

Paragon Visual supplies OEM HP inks for every DesignJet and supports easy cartridge recycling through HP Planet Partners

Tags:

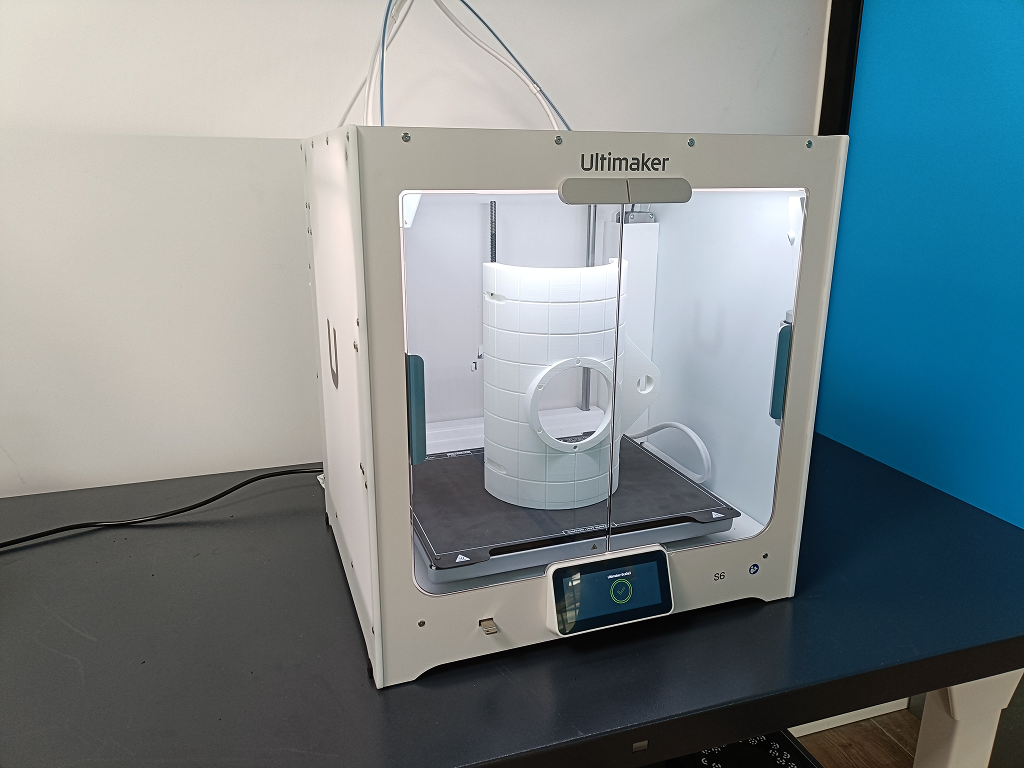

At Paragon Visual, we love spotlighting how real-world 3D printing applications are driving innovation across industries. This week, we’re excited to share an impressive project where a custom-designed drone bracket was developed using the UltiMaker S6 and PET CF filament — demonstrating just how effective additive manufacturing can be when paired with the right tools.

The part was produced entirely in-house and designed to support humanitarian efforts in mine detection using advanced drone imaging systems.

The challenge was to create a drone-mounted bracket capable of securing both thermal and RGB cameras used to scan for plastic landmines in conflict zones. This dual-purpose camera system required:

Every element of the bracket’s geometry was optimized using UltiMaker Cura, the industry-leading slicing software that offers advanced controls for material usage, infill, wall thickness, and support structures.

The bracket was 3D printed using the UltiMaker S6, a dual-extrusion professional printer ideal for complex mechanical parts and functional prototypes. To ensure strength without adding weight, the team used PET CF — a carbon fiber-reinforced filament with high rigidity, temperature resistance, and dimensional stability.

The final part included:

Using UltiMaker Cura, the team was able to reduce the total print time from over 10 hours to just 3 hours and 12 minutes — a 65% improvement without compromising structural quality.

Advanced slicing techniques allowed them to:

The UltiMaker S6’s precision print bed and closed front enclosure further ensured that the carbon fiber filament performed reliably across multiple print cycles.

This project showcases the best of what’s possible when you combine professional-grade 3D printing hardware, high-performance materials, and expert design practices:

At Paragon Visual, we support professionals in aerospace, education, manufacturing, and defense with 3D printing solutions that help you move faster and smarter.

Looking to explore functional printing, optimize workflows, or bring your prototyping in-house? The UltiMaker S6, paired with materials like PET CF, offers the power and precision to take your ideas from sketch to sky.

👉 Explore UltiMaker 3D printers »

👉 Need help choosing the right printer or material? Talk to our team »

Source: Adapted from Ultimaker. Original article available here

Tags:

Upgrade your printer, get up to $1,200 cash back.

Now through September 30, 2025, HP is rewarding you for upgrading your large-format printer. Trade in your old plotter—any qualifying inkjet or LED model—and receive up to $1,200 back when you purchase or lease an eligible new HP DesignJet printer.

Whether you’re printing CAD drawings, GIS maps, retail graphics, or photo-quality visuals, HP DesignJet has a wide-format solution built for your needs.

Choose from a wide range of qualifying HP DesignJet models—whether you’re looking for high-end photo production or powerful multifunction CAD printing. Explore the eligible printers below to see how much you can save:

👇 View the full list of qualifying models and rebate amounts:

Recycle your old printer responsibly with HP Planet Partners »

Contact us today to learn more!

🌎 Recycle your old printer responsibly with HP Planet Partners »

See all our printers: Learn More

Looking to see if your current printer qualifies? HP accepts a wide range of large-format inkjet and LED printers—including legacy HP DesignJet models and competing brands like Epson, Canon, Xerox, and Ricoh.

👉 Download the full list of eligible trade-in models (PDF) »

This PDF includes all qualifying models by brand, technology type, and size (36″ or larger). Be sure to review the list before submitting your rebate claim.

Tags:

At Paragon Visual, we love spotlighting real-world examples of how 3D printing drives innovation. This week, we’re showcasing a 3D printed protective lab case designed to safeguard fragile glassware in high-precision environments.

In environmental and chemical labs, precision glassware can be costly—and it’s often vulnerable to breakage during handling or storage. Apria Systems’ project engineer, Andrés Del Castillo Martín, needed a fast, effective way to protect this glassware without relying on expensive machining or slow traditional fabrication.

Instead of outsourcing or waiting on traditional production methods, the team used PLA filament and the UltiMaker S6 to design and print a custom four-piece protective case. The entire process took just 8 hours—produced entirely in-house.

What makes this case stand out?

This project demonstrates the power of the UltiMaker S6 to deliver fast, polished results in high-precision environments. With advanced motion control and optimized print speeds, the S6 empowers R&D and lab teams to iterate quickly and produce durable parts in-house—saving both time and cost.

Paragon Visual partners with organizations across Florida and beyond to help implement smart additive solutions. Whether you’re printing prototypes, tools, or final-use parts, we’re here to support you with hardware, materials, and expertise.

📩 Contact us today to learn more about the UltiMaker S6 and other advanced 3D printing systems:

Source: UltiMaker – Application of the Week: Protective Case for Custom Glass Labware

The UltiMaker S6 delivers professional-grade performance with up to 4× the output of the S5. Featuring the advanced Cheetah motion planner, a dual-extrusion print head, a flexible heated build plate, and full cloud connectivity, it’s the perfect solution for fast, reliable 3D printing across prototyping, tooling, and production applications.

Tags:

No account yet?

Create an Account